Robotics

I have been interested in robotics since my childhood. I am particularly drawn to how robotics can be used to better humanity and make production lines more efficient. Up until June 2023, I worked as a researcher at the Center for Advanced Manufacturing in the Realization of Robotics Systems Lab. Below are some of the projects I've worked on.

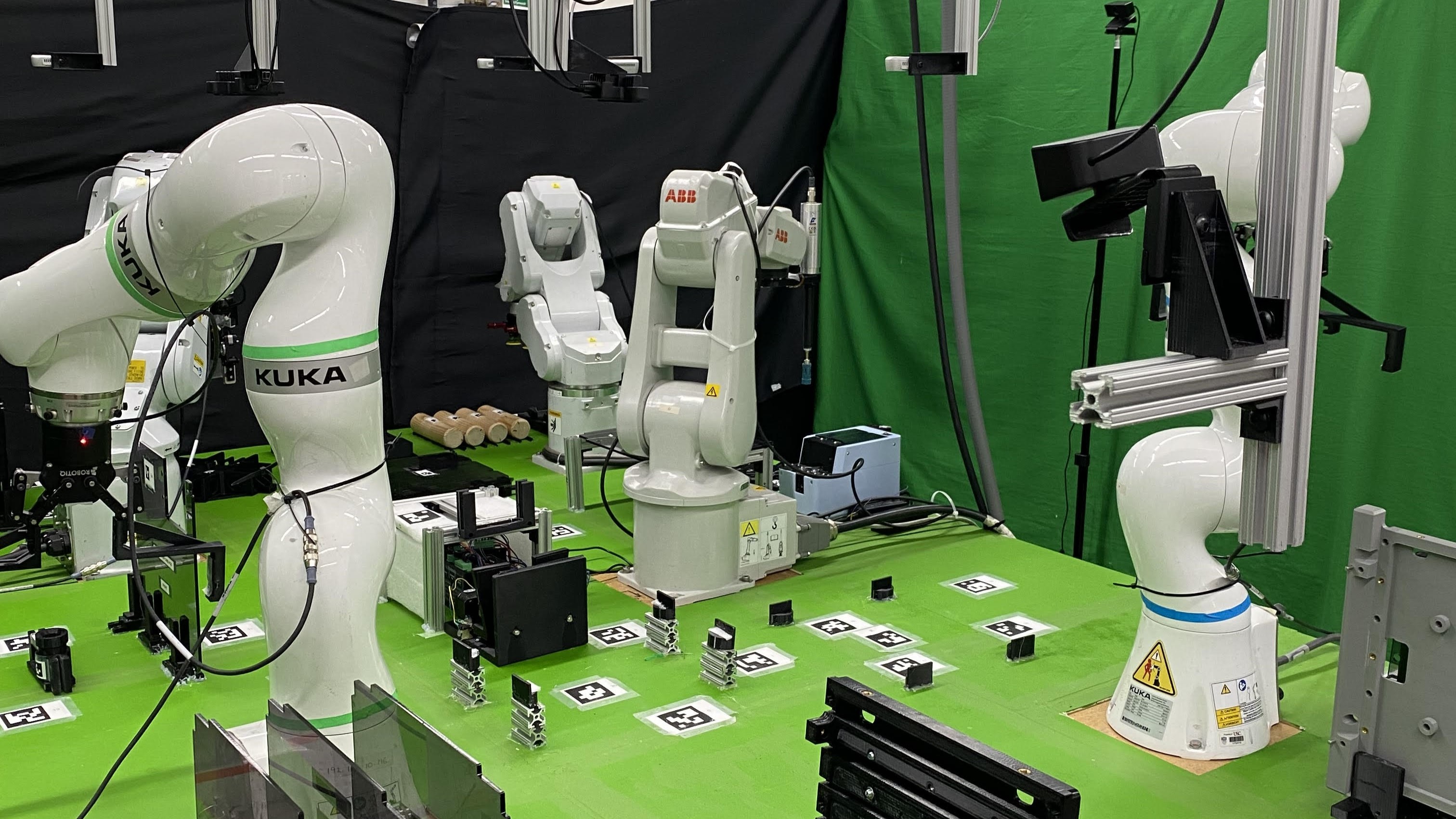

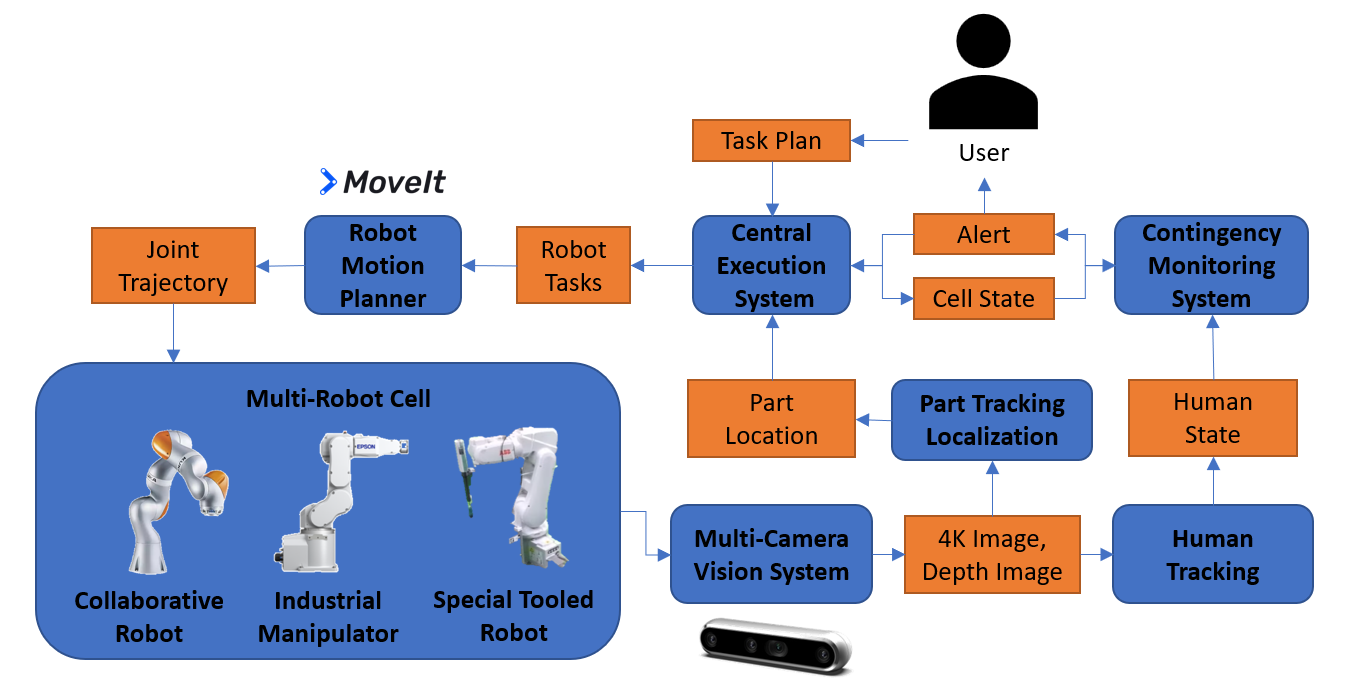

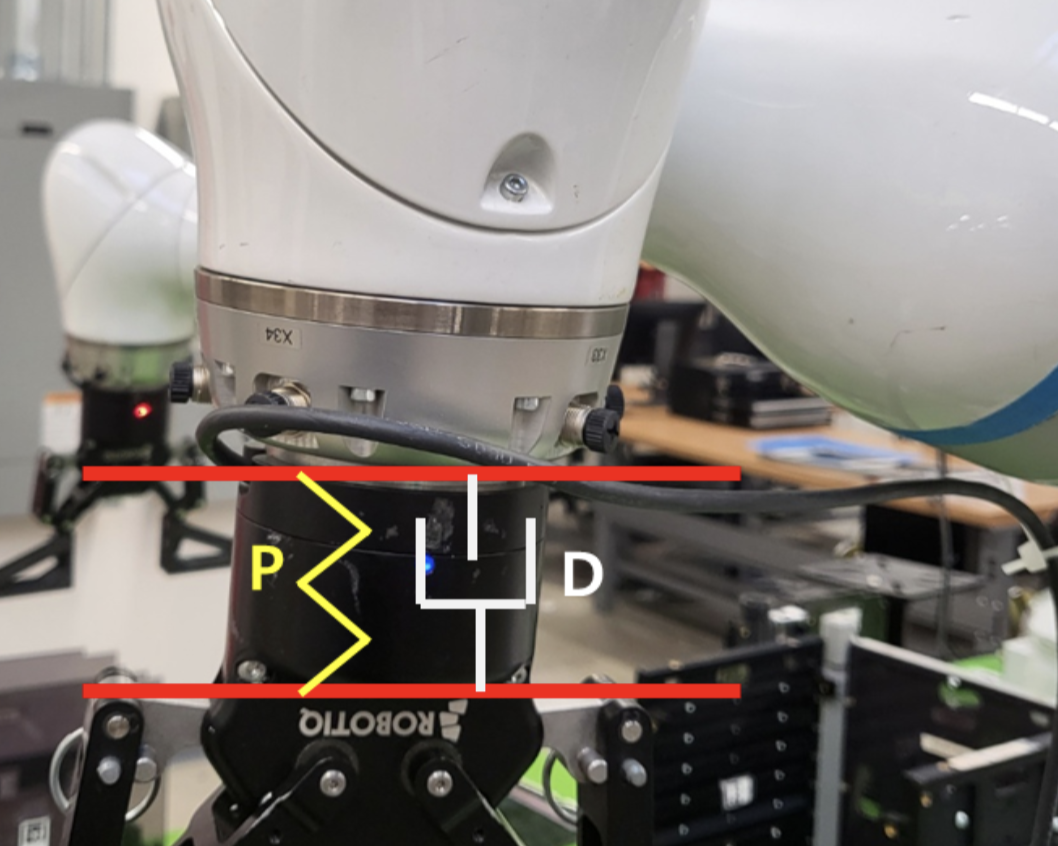

Rapidly Reconfigurable Robotic Satellite Assembly Cell

I led a team of 9 for 8 months to design and deploy from the ground-up this state-of-art cell. We have successfully demonstrated with this cell that a human and robot collaboration framework can be used to perform complex assembly operations in high-mix low-production applications. This project was featured in IEEE Spectrum and ICRA 2023.

Capabilities of the cell

- Artificial Intelligent Path Planning with vision-based part localization and tracking

- Digital Twin integration between Webot Simulation and MoveIt for unexpected contingencies during assembly

- Gesture recognition and human tracking allowing for human collaboration

- Fixture-free environment for rapid reconfiguration of cell

Machine Tending using Mobile Manipulation Webot Simulation

Machine Tending is already widely used in the manufacturing industry and is almost the foundation of a multi-degree robotic arm. The main goal for this project is to simulate the entire process of machine tending in Webots, including but not limited to the path planning of the mobile base with mecanum wheels and the motion planning of the UR5 robot arm.

ActiveTrack quality control testing

The ActiveTrack devices being developed for a study for the UC Berkeley/ UC San Francisco Ergonomics Program needed to be calibrated and put through a 15-hour testing cycle to make sure the posture states were being detected correctly. I built a robotic arm that would carry 10 devices at a time and run for at least 12 hours going through all the posture states the devices needed to detect.

Characteristics of robot arm

- Custom designed and soldered power distribution board for the servos

- Smoothing algorithm for servo motors

- Arm and base were laser cut

Areas of focus:

Multi-robot assemblies

Impedance Control

Path Planning